How Tpms Can Grow Your Tire Business (Part 3/3)

Posted by Jimmy Hill on

Email: jimmy.hill@alltiresupply.com

An Interview with Anthony Ableman, TIAA Certified Instructor, Director of Operations at All Tire Supply LLC, Houston, Texas (www. alltiresupply.com)

An Interview with Anthony Ableman, TIAA Certified Instructor, Director of Operations at All Tire Supply LLC, Houston, Texas (www. alltiresupply.com)

Anthony’s background and experience in the tire industry

Anthony is the second generation in the tire and wheel industry with a specific concentration in tire repair and tire and wheel service. He is a Tire Industry Association (TIA) Certified Advanced Instructor for Automotive Tire Service. He have also completed internal training programs from our suppliers on tire changing, tire repairing, wheel vibration, wheel balancing, TPMS, and vehicle lifting.

Part 3/3: 9 Awesome Tips To Grow Your Business With Tpms

TIP#1: Different Types of TPMS Systems

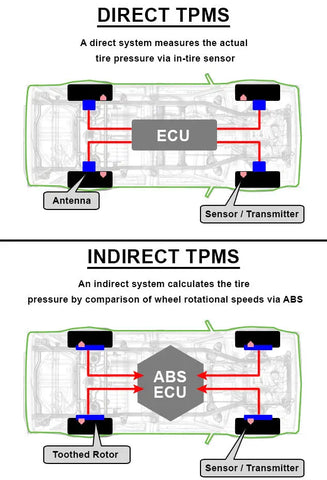

It’s important that the service centers know the two different kinds of TPMS systems that vehicles may be equipped with. There are both direct and indirect systems. Direct systems feature some kind of pressure sensor inside of the tire and wheel assembly. Usually these systems are mounted to the valve, on some older Ford and Mazda vehicles, a sensor that was mounted on a cradle and strapped to the inside of the wheel well was used. Both systems are supposed to meet minimum monitoring requirements from NHTSA, alerting the driver when one or more of the tires are 25% below the recommended inflation pressure listed on the vehicle placard.

The main advantage for the indirect system is that it is cheaper for the vehicle manufacturers to equip the vehicles with this technology and ultimately cheaper for the driver to maintain. There are still some questions about the system’s ability to alert the driver in a situation of rapid pressure loss (like a tire failure, blow-out, or in the event that a tire was to become unseated from the wheel). Also, there seem to be some issues regarding alerting the driver when all tires or tires on the same axle become low at the same rate/time. The other main problem with this technology is that it can be easily worked around. A customer can initiate his own relearn process at a new tire pressure (which may be underinflated) but this will cause the light to go out, making the system capable to appropriately and safely monitor inflation pressure

The main advantage of direct systems is accuracy. Since there is a specially designed sensor installed for the purpose of recording and communicating tire pressure data, that’s exactly what this sensor does; also, there is talk of making these sensors capable of monitoring tire pressure and other diagnostic data, allowing service centers more information in providing tire and wheel related service. Another thing that direct systems allow for is stationary monitoring. Indirect systems require that the wheels be moving for the systems to monitor; direct monitoring allows the system to monitor tire pressure while the vehicle is stationary - even off. When the vehicle is started, the pressure light will be illuminated, letting the driver know that there is a pressure problem. A real-world scenario where this is applicable would be where a driver picks up an object on the way to a location and is unaware. When the driver returns to his or her vehicle, if the loss in pressure were substantial enough, the TPMS light would illuminate, drawing attention to the tires, and allowing the driver to either change the tire or make arrangements for the vehicle to be towed to a service facility or remedy it some other way. If this same scenario were to happen on a vehicle with indirect monitoring, that same driver would not be aware until up to about 10 minutes of driving. That could be on an interstate or some other busy road. Furthermore, some direct systems will alert the driver of which particular tire is low, further reducing diagnosis times.

TIP#2: The Importance of Training

TIP#2: The Importance of Training

Training technical and customer-facing staffs are two sides of the coin for TPMS success. Training technical staff on the how to perform diagnosis and best-practices like test-before-touch really make a difference in quality of service and customer care. Understanding the particulars about on-going valve and wearable component service are integral for economic success for the shop as well as providing proper service. Training customer-facing staff like service writers or counter sales staff is also important. Using point-of-sales materials like counter mats, or displays are integral. This is something that is inside the tire so trying to sell the customer something they can’t see is obviously difficult; get the item where the customer can see it will make it easier to sell.

TIP#3: Connecting with a Reputable Distributor/Service Provider

In the automotive aftermarket, it is very important to link-up with suppliers that are well trained in the industry. Look for distributors with TIA Certified staff in your field (i.e. if you specialize in passenger and light-truck applications, seek a distributor with ATS certified staff, if you’re specialty is commercial or over the road truck, seek a distributor with CTS certified staff). Reputable distributors will have a host of suppliers and good quality products that will allow shops to deliver appropriate, professional products at prices that are competitive and good distributors will also offer training for technical staff, sales staff, and should offer after-sales support. When it comes to TPMS, distributors should know how to perform relearns, program sensors, and execute valve service. Distributors should be engaged and offer a multitude of products to create the right mix of products for their customers (tire dealers and service centers) to execute tire and TPMS service efficiently. Furthermore, good distributors should listen to warranty and service concerns from their dealers and take those to the manufacturer or to their supplier for resolution. A good distributor is a partner for their customers; distributorship goes far beyond sales, it extends deep into the realm of solving customers’ problems and being a true resource for those who work on the retail side of things.

TIP#4: Optimize Revenue and Profitability for Tire Stores, Tire Dealers and Shops That are Already Using TPMS

If you are a tire dealer and/or service center that is already servicing TPMS: bravo. The best ways to build on that service would be to standardize and practice consistency with the service and execute best practices on a regular basis. Are the service writers performing test-before touch in the service lane before the vehicle is being pulled into the bay? If not, are the technicians performing this step before the wheel is taken off of the vehicle? Is the shop servicing all of the wearable components whenever the bead is loosened from the rim? The reality is that the shop is already executing the majority of this work, but is the shop communicating to the customer what it’s doing? Are patrons being told that all procedures being followed? If you are performing these kinds of services the next level is standardizing them so that every patron is receiving that level of service regularly and then ensuring that the delivery of that service is being communicated to the customer: tell your customers how great you are.

TIP# 5: Overcome Common Obstacles to Successful Implementation

One of the most common questions I get when tire dealers want to begin TPMS is what to charge. My recommendation is to get a feel for what the market will bear in the market place. Go to the big chain stores around you and see what they charge and position yourself accordingly. Should you be higher because the quality of the service is greater? Should you be lower, because that’s your strategy? I don’t know the answer to those questions, but if you’re selling tires, then you already have pricing experience. My personal preference is to itemize things, charge for the parts, labor, new sensor, diagnostic fees etc. Again, my thing is to show the customer what they are getting. If they were to take that bill or quote somewhere, a competitor might beat your price, but are they offering everything that you are? If you bill everything out at one flat charge, let’s say you build it into “tire mounting” then someone can probably beat your pricing because they are also billing for “tire mounting” but that’s literally all they’re doing. Even if you don’t want to charge for it, I would still bill it out at $0.00, not saying you should, but it’s a differentiator.

The most difficult thing about successful implementation is getting a good product mix. Luckily, things have changed a lot since the early days of TPMS implementation and thousands upon thousands of dollars of inventory just to stock the right number of sensors is no longer necessary. All a tire service center needs is a good tool (again, look for one with OBDII capability and a pedigree in the Original Equipment market). The next thing to look for is a quality sensor. Again, look for one with a pedigree in the Original Equipment market. I cannot stress having a working experience with the vehicle OEMs enough; we are not talking about a pair of needle nose pliers, TPMS sensors utilize software, and complex proprietary programming languages to communicate with the vehicles, using non-OEM components means relying on some factory off-shore to get their reverse-engineering right. Sensor manufacturers that have working relationships with vehicle OEMs already develop those communication languages with the vehicle manufacturers, or work with manufacturers directly to get them. That same technology goes into those products they develop for the aftermarket. Aftermarket-only manufacturers don’t have those connections, do not care to develop them, and their products are neither tested nor developed to the same standards as OEM products. You really do get what you pay for regarding TPMS sensors. The last component is valve service and service packs. I would recommend to start off with a kit of service packs on popular vehicles, so the shop can get used to what kind of vehicles are coming in and replenish as necessary. A toolkit is also nice to have to execute proper service and will group all the torque tools necessary (valve core, T-10, T-20, in-lbs./N.m. torque wrench w/ 11mm and 12mm sockets).

TIP#6: How to Market TPMS

The best way to market TPMS is to have a conversation with your customers. Counter mats help, wheel cut-outs help, but those are tools to help the sales staff illustrate the point; they won’t do the talking themselves. POS materials help as much as tires on the show-room floor. They allow your customers to feel more comfortable but they won’t do the selling. The main thing that I would focus on is that TPMS is fundamentally a safety measure, like airbags, but they require more service than other safety systems on the vehicle - the main differentiator is that these directly pertain to the only means that the vehicle actually contacts the road (on most vehicles that’s less that one square foot) and TPMS is an integral piece to the puzzle to keep that one-square foot contact patch performing the way it should.

TIP#7: What is the Cost Range for Equipment/Supplies to Get Started.

I would budget about $2,000 to $5,000 when it comes to outfitting a shop reasonably and professionally for TPMS service. Even the $2,000 will get you a professional level tool, some programmable sensors, torque tools, and some service packs. If the shop is large and needs multiple tools, I would budget accordingly. If the shop in question is a premium or high-end facility, I would also add a lower-function tool to use as a counter service or test-before you touch tool. This would be ideal if the service writer were to perform a walk-around of the vehicle with the customers and check things like tire tread depth, alignment or tire wear, pressure, wiper blades, inspection (if applicable) etc. TPMS should be part of the pre-work vehicle inspection for two-reasons: it will reduce liability (if the customer is made aware of a problem before the vehicle is in the way, it’s very cut and dry that the customer brought the vehicle in broken and also so that every vehicle is checked for another source of revenue).

TIP#8: How TPMS Service is an Integral Part of the Tire Sales and Service Cycle; Future Demand for TPMS.

This, I think is something that is largely overlooked. The RMA has for some time essentially “required” or defined valve replacement as a necessary part of a complete tire changing procedure as outlined in their most current edition of “Care and Service of Passenger and Light Truck (LT) Tires” publication. In the same aforementioned publication, they go on to “strongly” recommend that wearable components of the TPMS system be replaced as well, but have so far refrained from using language so strong as to require it. As of Q2, 2015 I anticipate their language to be more consistent with that of the TPMS component manufacturers in the near future, perhaps by the end of the year. That being said, so many tire retailers have changed out the TR 413 or TR 418 valve without even thinking about it when servicing wheels for so long and now, with the advent of TPMS, there is a small computer attached to the end of the valve and so many adopted a hands-off policy as a means of liability mitigation. That mitigating of liability has also reduced revenue! It seems that the small sensor at the base of the valve has prevented them from seeing rather normal looking snap-in valve that the sensor is attached to. Clamp-in components are a bit more complicated, but there are plenty of places to find the requisite information and quite a few outlets for tire dealers to get their hands on the actual parts. We have completely embraced TPMS and provide support to our customers by keeping a full stock of valves and service packs

TIP#9 Where to Go for More Information

For more information, customers shouldn’t hesitate to contact us, or their distributor for questions (and answers) about TPMS service. If looking on the web, I always recommend the following sites:

- Dill has some great videos available: http://dillaircontrols.com/dill/tpms-videos/

- Bartec has some good videos related to their tools: https://www.bartecusa.com/tpms-videos

- Schrader has the most comprehensive selection of TPMS videos that I have seen available so far. You can see their YouTube page here: https://www.youtube.com/user/SchraderInnovation

Share this post

0 comment